Our Hallmarking Methods

Sampling and Assaying

Sampling is the selection of articles from the packets which will then be assayed. This is done according to set sampling rates based on detailed statistical analysis.

Assaying is the analysis of an article's composition. These days the vast majority of assaying is carried out by X-ray Fluorescence Spectroscopy (XRF) which is an entirely non-destructive technique and gives the fineness of the metal in less than 30 seconds. On occasion it may be necessary to remove the surface layer to ascertain the alloy underneath.

Occasionally, traditional methods for assaying are used which include touch stone testing, cupellation, silver titration, and platinum and palladium testing using the ICP-OES (Inductively Coupled Plasma Optical Emission Spectroscopy). For all the traditional methods excluding touch testing, a physical sample must be taken from the article by scraping/drawing.

- Gold cupellation - A 2000 year old small refining process where the pure gold portion of a gold alloy is separated from the base metals in order to calculate the % gold content overall.

- Silver titration - Analysis of the pure silver portion within a silver alloy. Platinum and palladium testing using the ICP-OES (Inductively Coupled Plasma Optical Emission Spectroscopy).

More information can be found in Laboratory Services.

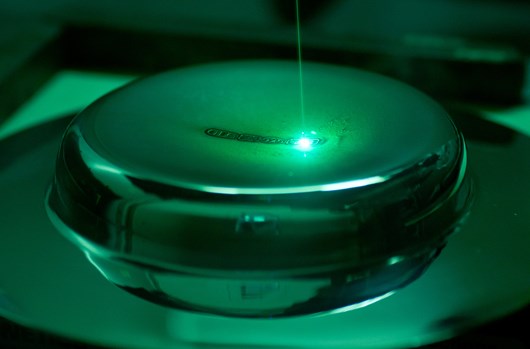

X-ray florescent spectrometer giving reading of alloy contents

Touch testing a ring

Touch testing dates from 500BC. We first used the technique alongside physical removal of sample to determine homogeneity. Still used for big packets. Traditional sampling involves a series of ‘touch tests’. In the touch testing process, the articles are lightly rubbed onto a ‘touchstone’ made from basanite. This leaves a thin streak of material on the stone. Chemicals are applied to the smear and from the reaction that takes place, an initial indication of the fineness is determined. This is the origin of the phrase "coming up to scratch".

Complex Sampling

We are required by law to test a proportion of items submitted to us before hallmarking. On occasion items do fail for various reasons meaning, so to make sure we are applying the correct hallmark to all, we must test every single item, then separate them in to the appropriate standards if required.

If your items fail assay, a complex sampling fee could be applied. This surcharge amount is found in the Pricelist found in the Customer Info & Downloads section. The charged is applied to items tested and not just the items which fail assay.

If you do not wish to incur this additional charge, the items can be returned to you unhallmarked, you will still be liable to pay the original packet fee.

Any packet resubmitted for Hallmarking due to items failing Assay will incur normal charges upon resubmission.

We encourage customers to make sure items are conforming to the Hallmarking Act and are divided into packets according to our Submission Rules. Any items which do not conform to the Hallmarking Act will delay the service to your packet.

Read more about this in our Terms & Conditions, see point 6. in our downloads section here.

Marking

There are Three Types of Marking:

- Hand marking: Traditional Struck hallmarking by punch and hammer

- Press marking: Traditional fly press or air press marking

- Laser marking: the most recent method of applying the hallmark

Struck Marks

Traditional struck marks are made with a punch, creating an impression by moving (forming) the metal - this can leave a slight 'bruise' on the metal, or can distort it (depending on the thickness).

This can be removed by an experienced jeweller or silversmith by filing and finishing, a process known as 'setting back'. (See video).

If your work is unfinished, a struck mark is recommended as the result is deep, and can then withstand plating and general finishing. This hallmark will last a lifetime.

Handmarking is the most traditional method of hallmarking, and is carried out using a punch and hammer. This type of marking is not recommended for very thin metal, delicate or hollow articles.

Pressmarking is another traditional form of hallmarking. Essentially it is an automated version of handmarking with marks applied using fly press or air press. The process is often used for large runs of the same or similar type of article.

Laser Hallmarking

If your work is finished and polished, a laser hallmark is ideal as the process does not displace the metal so you won't need to set it back.

Laser Marks are made with either a fibre, lamp pump, or diode laser - all three are used across our offices. A very fine, high powered beam vapourises the surface of the metal and etches on the hallmarks.

Laser marking is the most recent method of applying the hallmark.

Laser hallmarking on flat articles is straightforward. Laser marking on curved articles is possible when the radius of curvature is sufficiently shallow to maintain focus (a smaller size/length mark often helps for those articles).

We currently offer two different types of laser hallmark:

- 3D laser mark: Creates a recessed background leaving the detail to stand proud. Would withstand a very slight polishing.

- 2D laser mark: Creates a simple outline of the hallmark. It is very light so strictly for finished items only.

It is great for marking thin, hollow or more delicate items. Raw castings and unfinished items are unsuitable as a laser mark can only withstand a light polish.

We also offer laser engraving services.

Comparison of laser mark (back sample) and struck mark (front sample)

Comparison of 3D laser (back sample) and 2D laser (front sample) marks

| Size | Height | User |

|---|---|---|

| A | 6.00mm | Large Silver Holloware |

| B | 5.00mm | Large Silver Holloware |

| C | 4.25mm | Large Silver Holloware |

| D | 3.50mm | Small Silver Holloware |

| E | 3.00mm | Small Silver Holloware |

| F | 2.50mm | Small Silver Holloware |

| G | 2.00mm | Small Silver Holloware |

| H | 1.75mm | Napkin Rings, Frames |

| I | 1.50mm | Napkin Rings, Frames |

| J | 1.25mm | Napkin Rings, Frames |

| K | 1.00mm | Solid Bangles, Large Jewellery |

| L | 0.75mm | Rings |

| M | 0.50mm | Small Jewellery, Rings, jump rings |

Both struck and laser hallmarks are available in sizes 0.5mm to 6mm (height). It is worth noting that when struck by a punch, the hallmark will appear very slightly larger.

When ordering a sponsor's punch online, our system guides you to choose a size most suited to the work you are sending to us in line with the chart shown here.

If you order a larger punch it is important to remember that it is more likely to distort and bruise your work because of the force needed to strike it, so you may need to set back the hallmark when you receive your items. This process flattens the impression of the hallmark on the reverse of your work. Consider that a large punch will be unsuitable for delicate items as the punching process will displace the metal.

The other component marks in the hallmark may be a different size at your request, or to suit the area. We select the size at our discretion if not specified.

Top: Swan Neck Punch, Bottom: Straight Punch

The image shows struck hallmark at top, and laser marks beneath

Development of Marking Technology

Download an article from the Goldsmiths' Technical Journal to read more about the development of both methods.

ON YOUR MARKS; THE DEVELOPMENT IN ASSAY OFFICE MARKING TECHNOLOGY