Punch Making

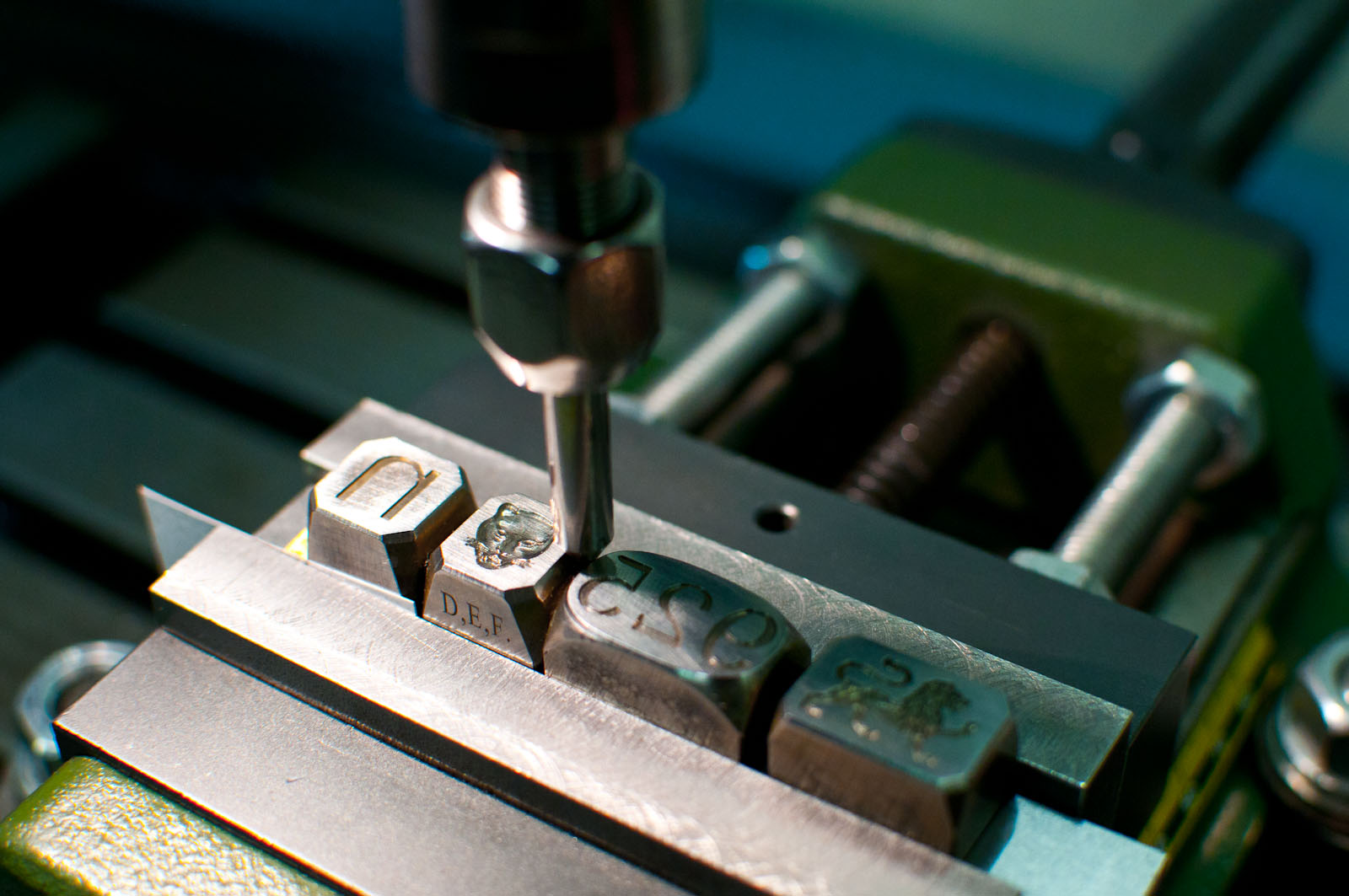

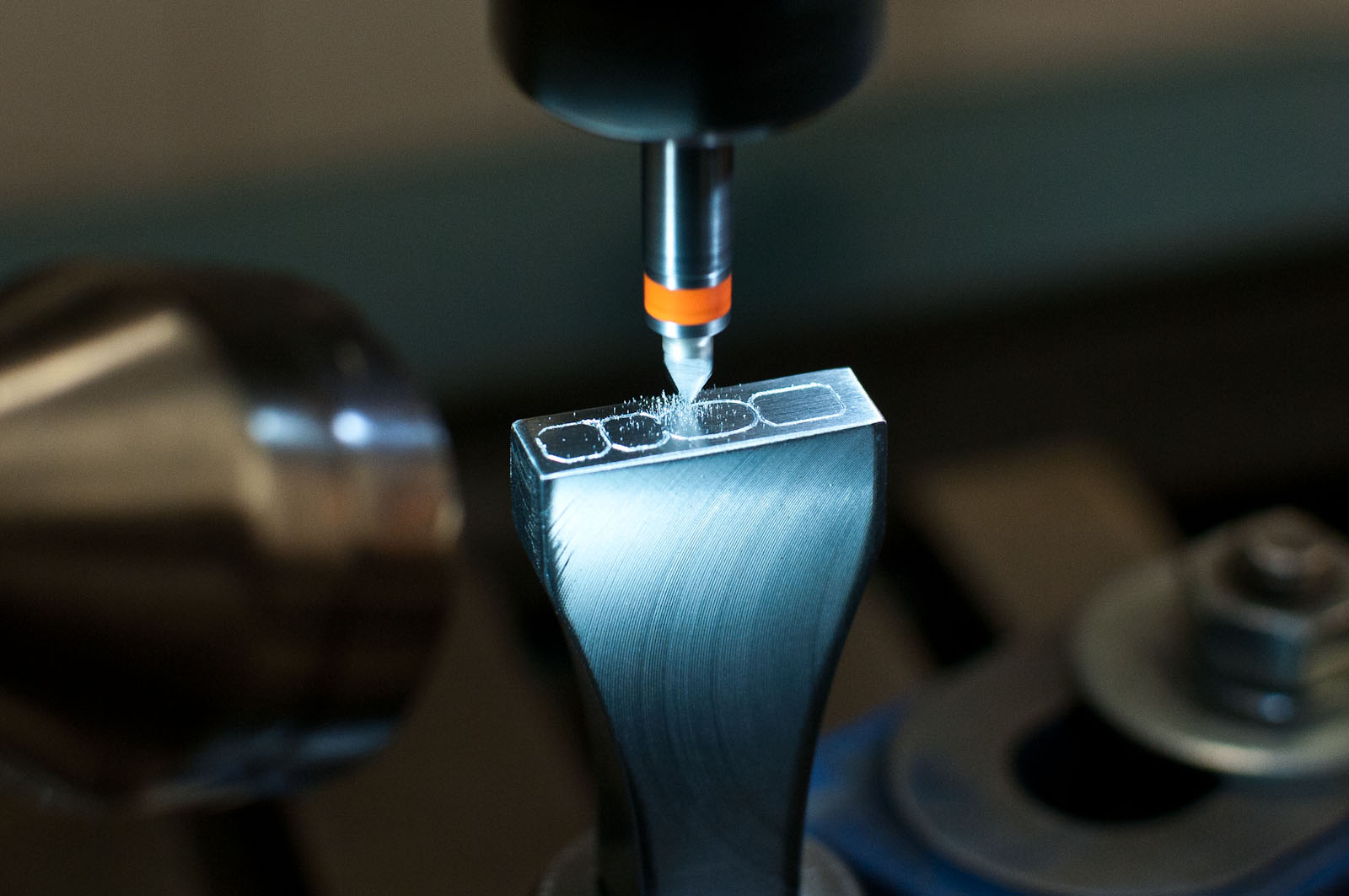

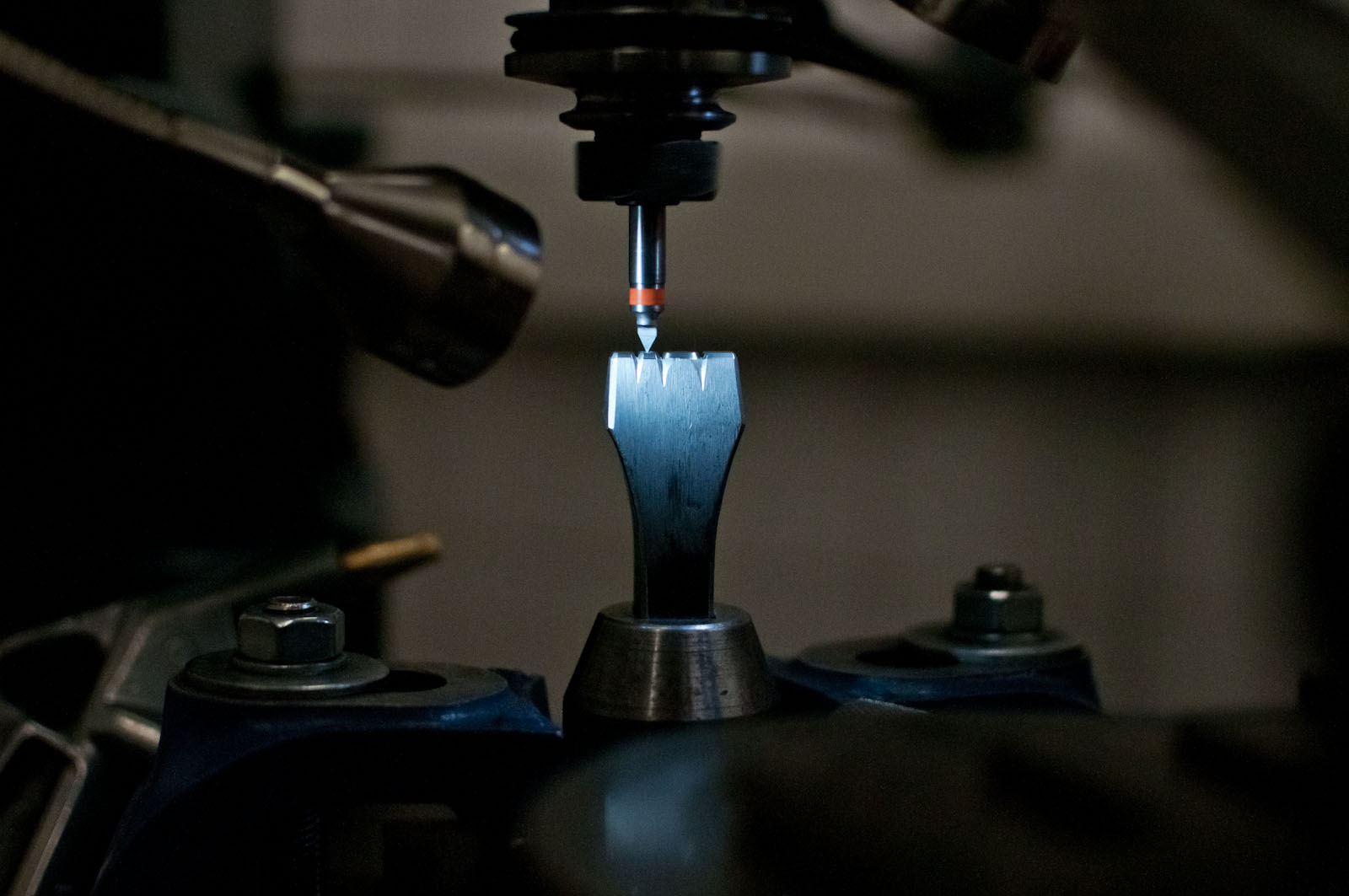

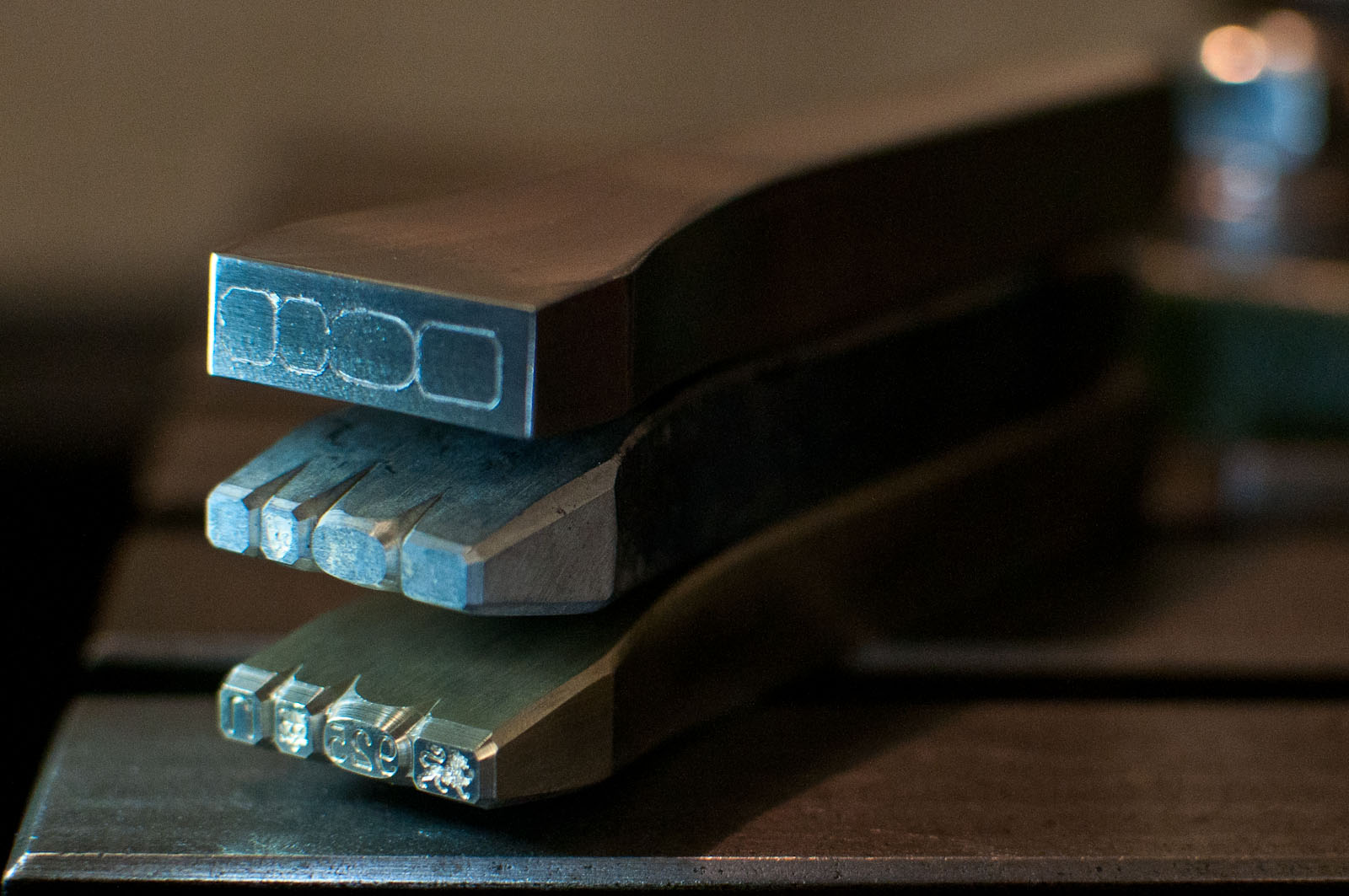

We have pantograph engraving and state-of-the-art laser machines that enable us to offer a fast and efficient punch manufacturing service. We can make flat or curved punches on 'traditional straight' or 'swan neck' shanks in our workshop at Goldsmiths' Hall. You will be required to provide us with the necessary artwork and then we can proceed.

The punches are cut by laser and finished by hand to an exceptional standard and are suitable for hand marking or marking by press. Punches can be made in a range of sizes from 0.5mm, with a nominal upper limit of 6mm.

Read more in the article in the Goldsmiths' Review 2011/2012 "Engineering Hallmarks".

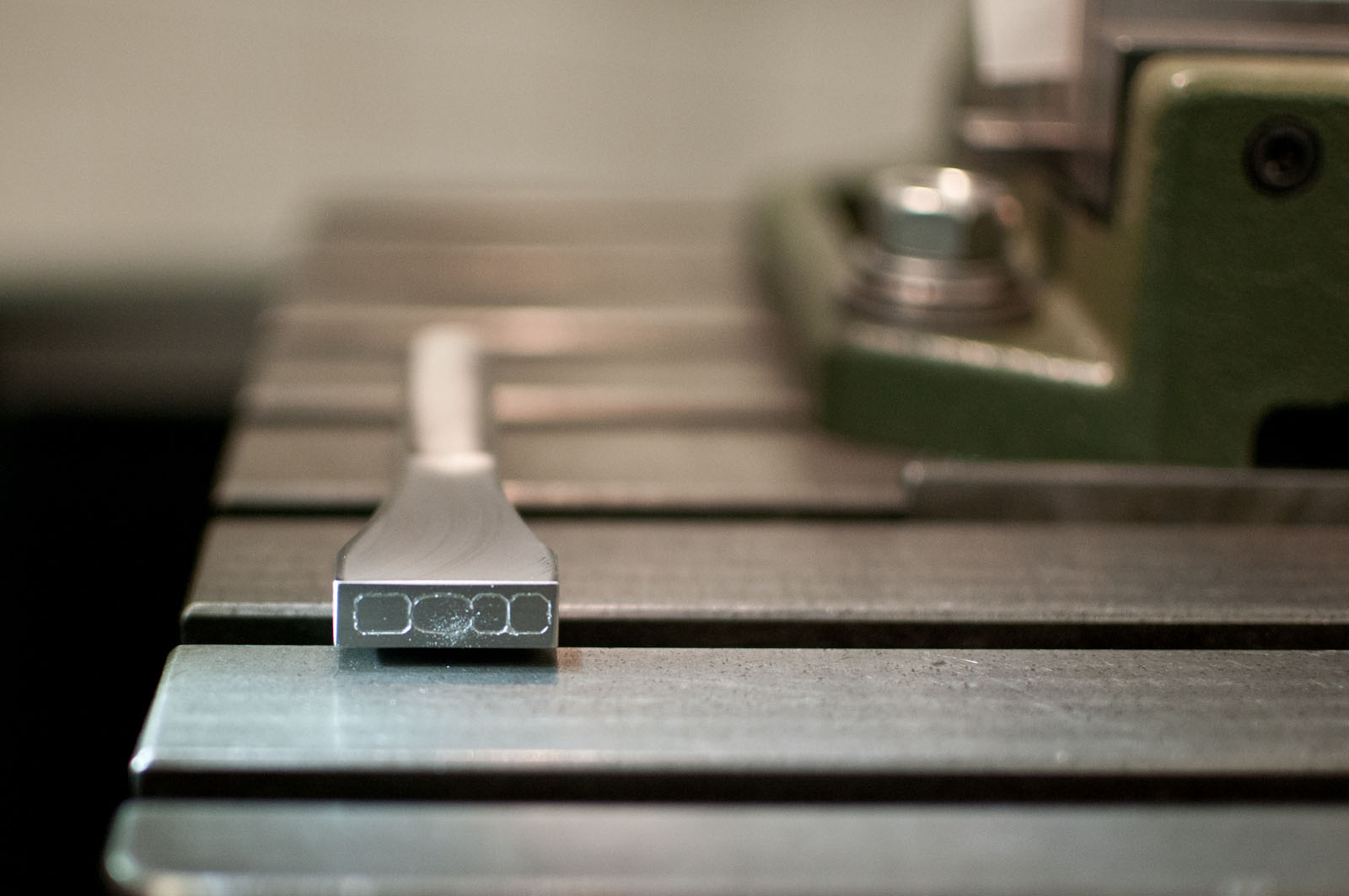

Straight punch stack

Need a new punch for an Existing Registration?

For more information on ordering a new punch please click here.